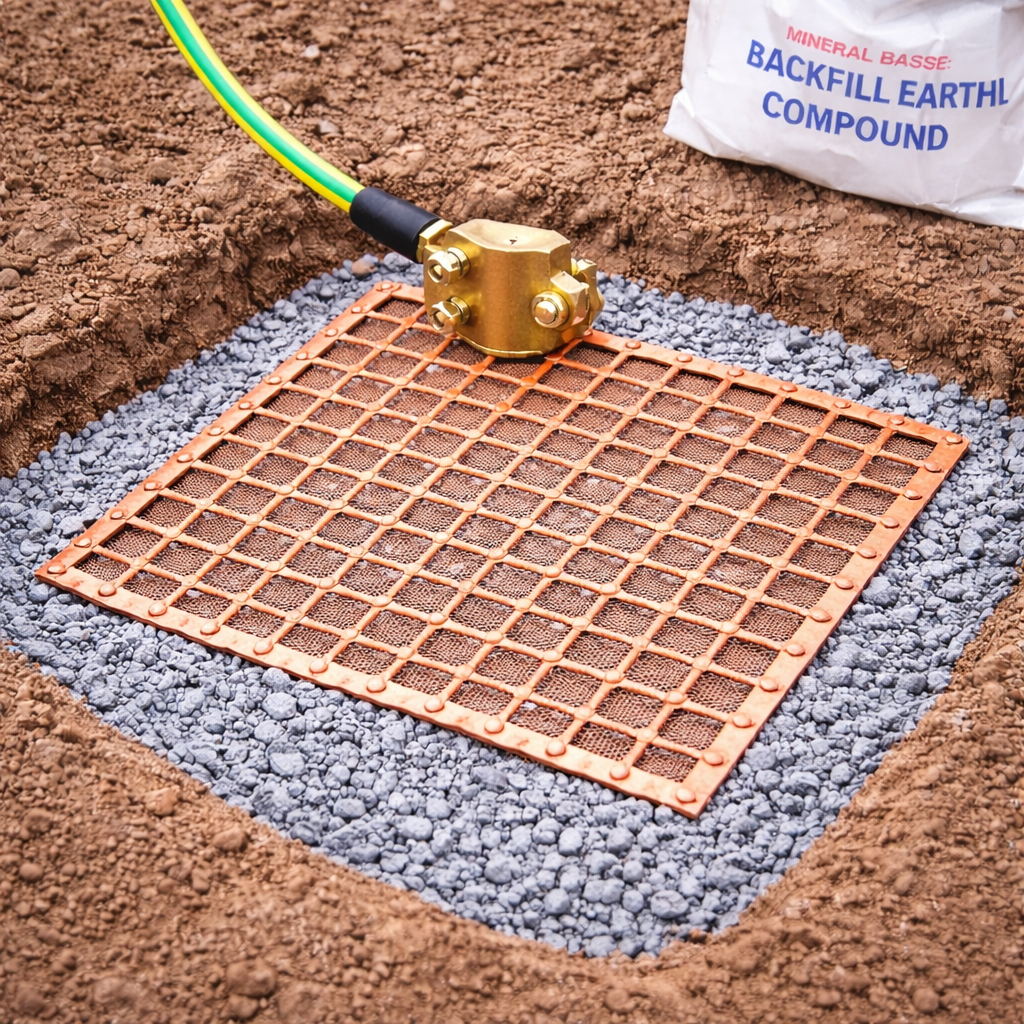

Mat Earthing System

Engineered Earth Mats (Grid Earthing) designed to minimize Step & Touch Potential in Substations and Industrial Plants. Compliant with IEEE 80 standards.

System Overview

Mat Earthing involves creating a horizontal mesh of conductors (MS Flat, GI Flat, or Copper) buried underground. This mesh connects all equipment structures to a single grounding system, creating an Isopotential Plane.

This is critical for high-voltage substations (33kV, 66kV, 220kV+). In case of a fault, the mat ensures that the voltage difference between a person's feet (Step Potential) or between their hand and feet (Touch Potential) remains within safe limits.

Why is Mat Earthing Critical?

Human Safety

Reduces Step & Touch Voltage

Fault Handling

Dissipates massive currents

Uniform Potential

Prevents equipment damage

Custom Design

Grid size as per soil test

Technical Data

Design Specifications

| Parameter | Standard Specification | Typical Value |

|---|---|---|

| Grid Material | Mild Steel (MS) / GI / Copper Flat | 50x6mm, 75x8mm, 75x10mm |

| Grid Spacing | Distance between conductors | 3m x 3m to 10m x 10m |

| Depth of Burial | Below Ground Level (BGL) | 500 mm to 1000 mm |

| Vertical Risers | Electrodes at corners | 3m GI/Copper Pipe or Rods |

| Jointing Method | Welding / Exothermic Welding | Overlap Welding |

We offer complete turnkey solution: Soil Testing -> Design -> Material Supply -> Installation.

Building a Substation?

Get expert consultation for Mat Earthing design and material supply.