Published on 30 January, 2026

Chemical Earthing vs. Conventional Earthing: Which is Best for Your Factory?

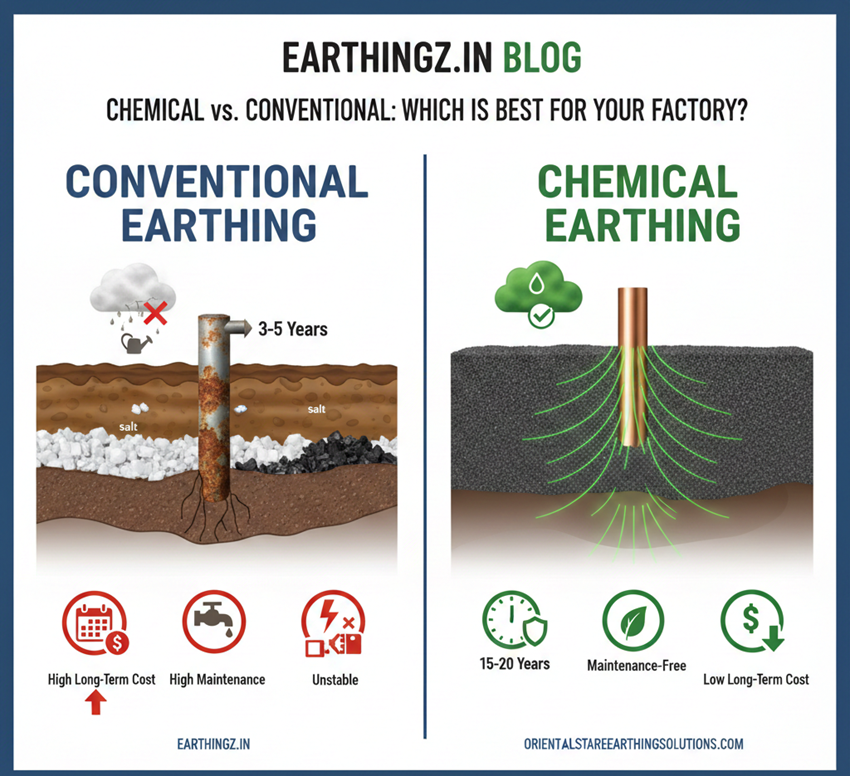

In the world of electrical safety, the foundation of every secure facility is its earthing system. For decades, the traditional Salt and Charcoal (Conventional) method was the standard. However, as industrial equipment becomes more sensitive and expensive, Chemical Earthing has emerged as the superior choice.

If you are a facility manager or a contractor in India, choosing the right system is a matter of long-term cost and safety. Let's break down the differences.

1. Life Span and Durability

Conventional Earthing: Typically lasts 3 to 5 years. The salt and charcoal mixture is highly corrosive, which eventually eats away at the GI pipe or copper plate.

Chemical Earthing: Designed to last 15 to 20 years. It uses a specialized Backfill Compound (BFC) that protects the electrode from corrosion while maintaining soil conductivity.

2. Maintenance Requirements

The biggest headache with conventional earthing is the need for constant watering. In peak Indian summers, the salt dries out, and the earth resistance ($R$) spikes to dangerous levels.

Chemical earthing is Maintenance-Free. The hygroscopic nature of the chemical compound allows it to retain moisture from the atmosphere, keeping the resistance stable year-round without manual intervention.

3. Earth Resistance

StabilityFor industrial machinery and sensitive electronics, you need a stable resistance, ideally below 1 Ohm.

Conventional: Resistance fluctuates wildly based on the season.Chemical: Provides a constant, low-impedance path to the ground, ensuring that your surge protectors and ELCBs (Earth Leakage Circuit Breakers) trip instantly during a fault.

4. Total Cost of Ownership (TCO)While the initial installation cost of chemical earthing might be slightly higher than a simple salt-pit, the long-term savings are massive:

No replacement costs every 4 years.

No labor costs for regular watering and salt refilling.

Zero downtime for your machinery due to earthing failure.

Comparison Summary TableFeatureConventional EarthingChemical Earthing (Earthingz)MaterialGI Pipe, Salt, CharcoalPipe-in-Pipe/Strip-in-Pipe, BFCSpace RequiredHigh (Large Pits)Low (Compact Boreholes)Soil ResistivityDependent on external waterIndependent (Chemicals boost conductivity)ReliabilityLow (Fluctuates)High (Stable)Conclusion: Why Choose Earthingz.in?At Earthingz, we provide high-quality Chemical Earthing Electrodes and Backfill Compounds that meet IS 3043 standards. Whether you are setting up a small workshop or a large-scale manufacturing plant in Delhi, Gurugram, or Dehradun, our solutions ensure your equipment and personnel stay safe.Don't wait for a fault to happen.Get a Free Quote for your Site Installation Today!

If you are a facility manager or a contractor in India, choosing the right system is a matter of long-term cost and safety. Let's break down the differences.

1. Life Span and Durability

Conventional Earthing: Typically lasts 3 to 5 years. The salt and charcoal mixture is highly corrosive, which eventually eats away at the GI pipe or copper plate.

Chemical Earthing: Designed to last 15 to 20 years. It uses a specialized Backfill Compound (BFC) that protects the electrode from corrosion while maintaining soil conductivity.

2. Maintenance Requirements

The biggest headache with conventional earthing is the need for constant watering. In peak Indian summers, the salt dries out, and the earth resistance ($R$) spikes to dangerous levels.

Chemical earthing is Maintenance-Free. The hygroscopic nature of the chemical compound allows it to retain moisture from the atmosphere, keeping the resistance stable year-round without manual intervention.

3. Earth Resistance

StabilityFor industrial machinery and sensitive electronics, you need a stable resistance, ideally below 1 Ohm.

Conventional: Resistance fluctuates wildly based on the season.Chemical: Provides a constant, low-impedance path to the ground, ensuring that your surge protectors and ELCBs (Earth Leakage Circuit Breakers) trip instantly during a fault.

4. Total Cost of Ownership (TCO)While the initial installation cost of chemical earthing might be slightly higher than a simple salt-pit, the long-term savings are massive:

No replacement costs every 4 years.

No labor costs for regular watering and salt refilling.

Zero downtime for your machinery due to earthing failure.

Comparison Summary TableFeatureConventional EarthingChemical Earthing (Earthingz)MaterialGI Pipe, Salt, CharcoalPipe-in-Pipe/Strip-in-Pipe, BFCSpace RequiredHigh (Large Pits)Low (Compact Boreholes)Soil ResistivityDependent on external waterIndependent (Chemicals boost conductivity)ReliabilityLow (Fluctuates)High (Stable)Conclusion: Why Choose Earthingz.in?At Earthingz, we provide high-quality Chemical Earthing Electrodes and Backfill Compounds that meet IS 3043 standards. Whether you are setting up a small workshop or a large-scale manufacturing plant in Delhi, Gurugram, or Dehradun, our solutions ensure your equipment and personnel stay safe.Don't wait for a fault to happen.Get a Free Quote for your Site Installation Today!

Hope you found this article helpful!